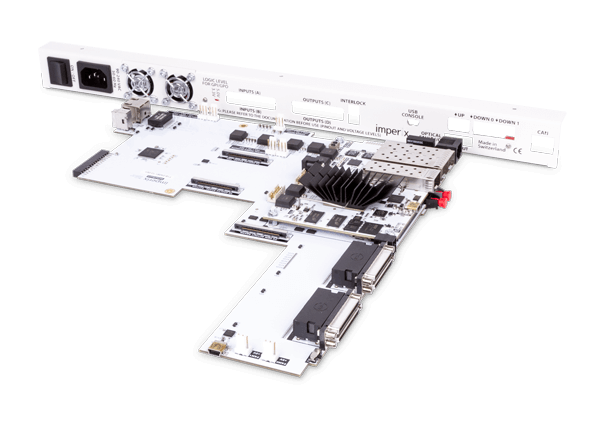

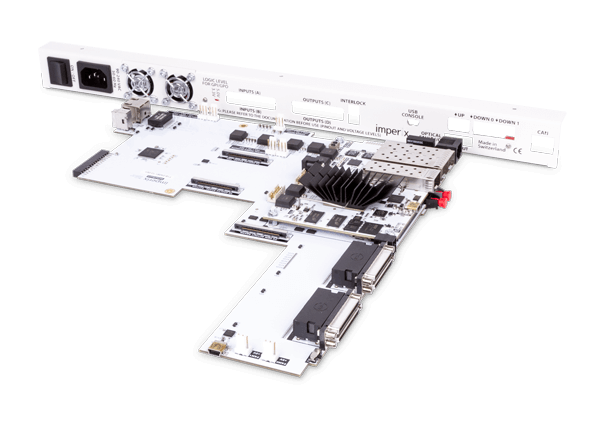

Rapid prototyping controller

B-Box RCP 3.0

Rapid control prototyping system

The ultimate DSP+FPGA rapid prototyping controller for power electronics

The B-Box RCP is a rapid control prototyping (RCP) system for power electronic applications. Thanks to the high flexibility of its software and hardware, it facilitates the experimental validation of power converters control techniques.

The system is fully programmable, including both its DSP and FPGA, so that even the most advanced control algorithms can be effectively tested in a laboratory environment. The RCP controller also supports real-time monitoring and debugging.

| |

your price | |

Upgrade kit

The kit allows transforming hardware from the previous generation (2.0) into the very same hardware as the B-Box RCP 3.0. The upgrade procedure implies replacing the motherboard – with its hosted processing module – as well as the rear panel. Updating the hardware is easy and can be done directly by the end-user, or at imperix (standard support request).

| |

your price | |

KIT COMPOSITION | |

| |

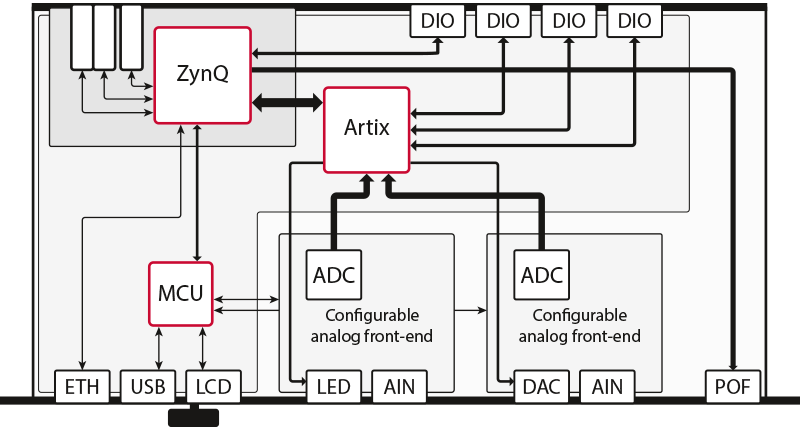

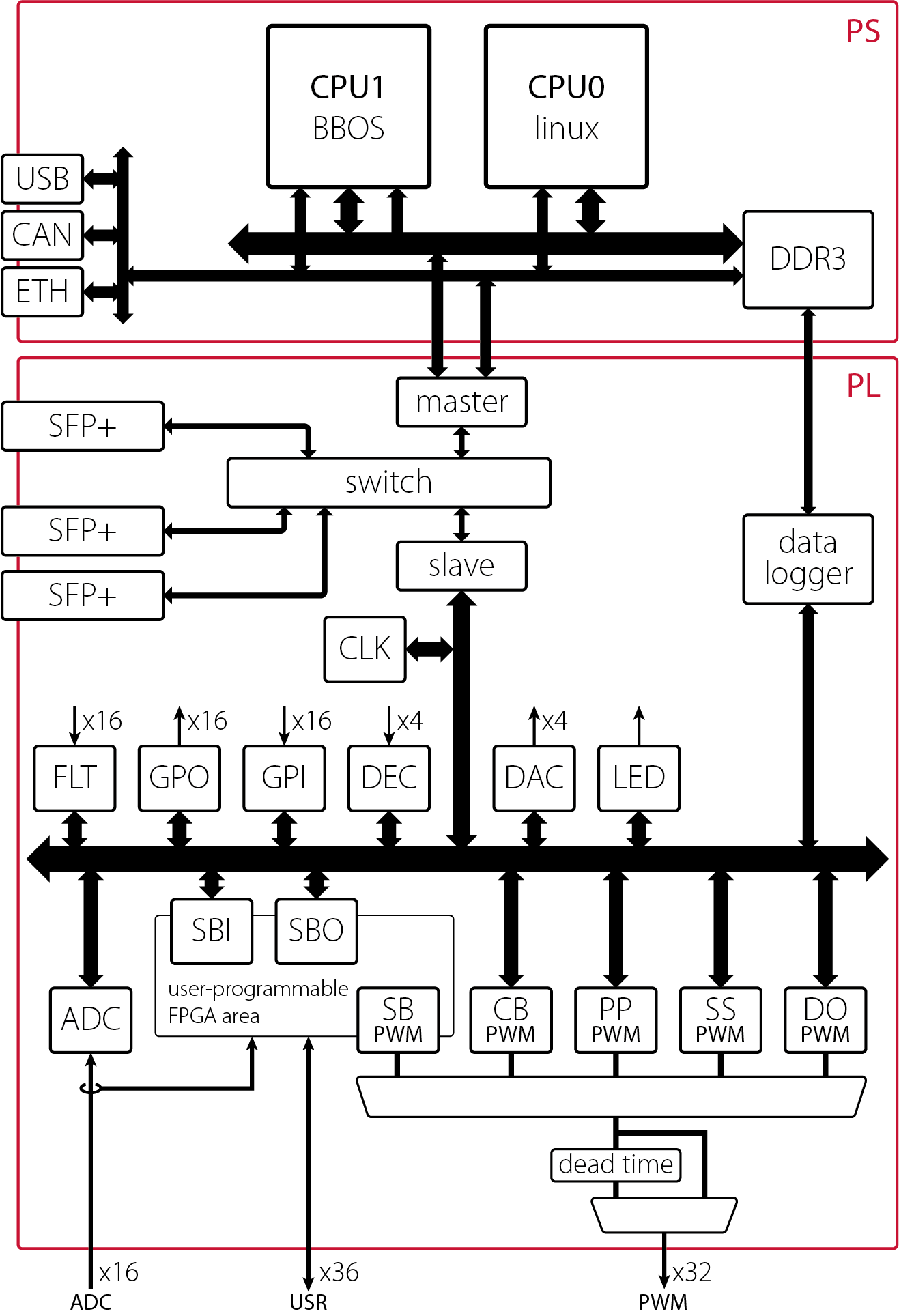

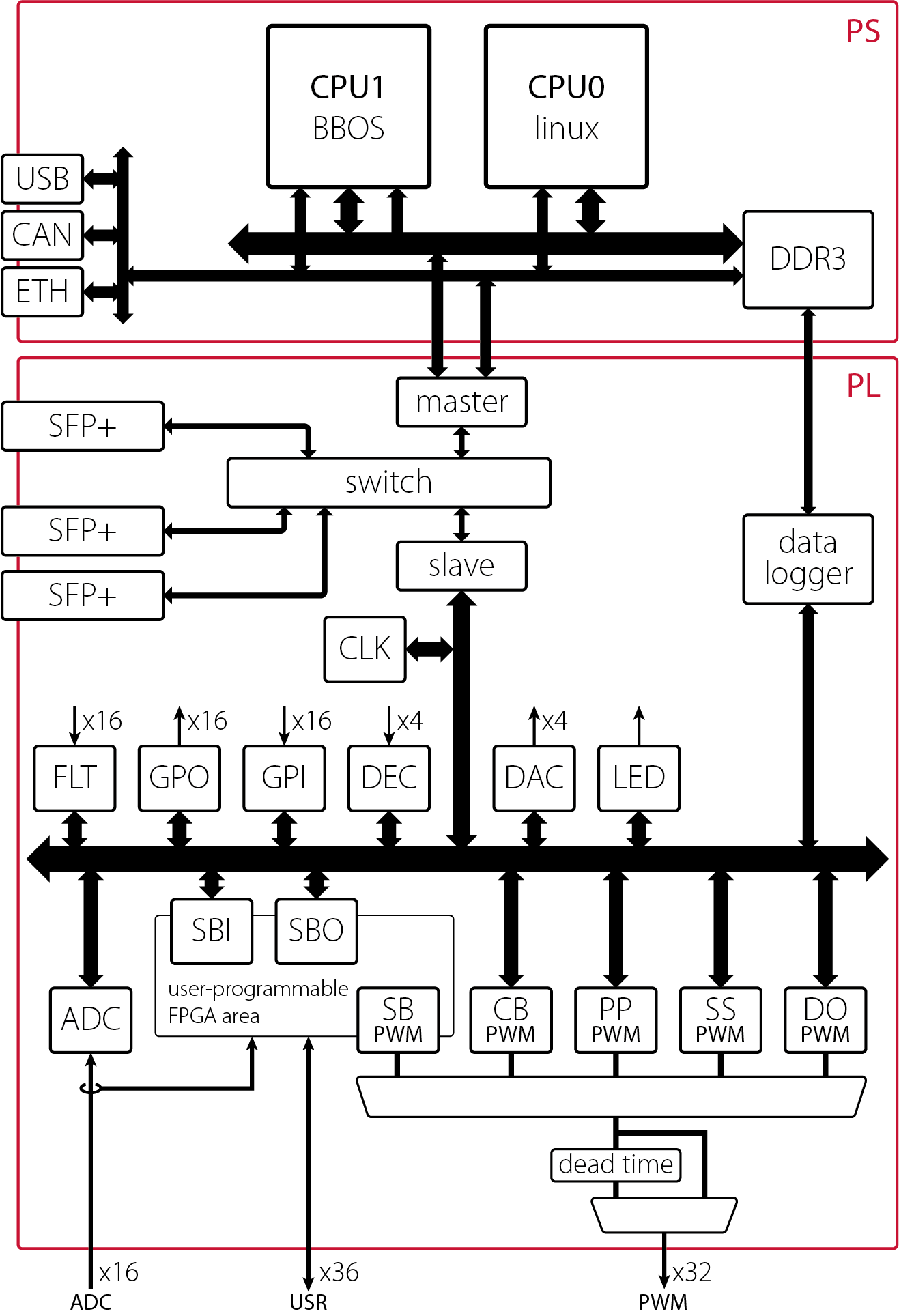

The control hardware is centered around a Xilinx Zynq 7030 SoC, with the fastest available speed grade. It features a dual-core ARM processor (DSP), clocked at 1 GHz.

Thanks to its Kintex-grade FPGA logic, the digital controller offers 32 PWM blocks, with a time resolution of 4 ns. This guarantees a duty-cycle resolution of 2 % at 5 MHz.

The rapid prototyping controller offers great flexibility for the most demanding applications, with an entirely configurable analog front-end and a large number of digital I/Os.

Connectivity for power electronics

Specialized I/O interfaces at the service of rapid prototyping

The control of power converters always requires various types of sensors to be connected to the control hardware. The B-Box RCP facilitates rapid control prototyping applications with a tailored and highly configurable connectivity.

Front view

Rear view

Main controller specifications

| System on chip | Xilinx Zynq XC7Z030-3FBG676E | Digital outputs | 16x Electrical (3.3V/5.0V) |

| DSP / Processing cores | 2x ARM Cortex A9 1GHz 1GB DDR3 | Digital inputs | 16x Electrical (3.3V/5.0V) |

| FPGAs | Xilinx Kintex 7 125K (user programmable) Xilinx Artix 7 35T (auxiliary) | Fault inputs | 16x Electrical (3.3V) 1x Electrical interlock 1x Optical interlock |

| Analog inputs | 16x 16bits @ 500ksps Simultaneous sampling Programmable full-differential front-end | Incremental decoder inputs | 4x 3-pins (A,B,Z) (shared with GPI inputs) |

| PWM outputs | 16x Optical (Expansion available) 32x Electrical (3.3V) | Communication | 1x CAN 1x Ethernet 1 Gbps 3x SFP+ 5Gbps (RealSync) |

| User High-speed I/Os | 36x Electrical (3.3V) |

| System on chip | Xilinx Zynq XC7Z030-3FBG676E |

| DSP / Processor | 2x ARM Cortex A9 1GHz |

| 1GB DDR3 | |

| FPGAs | Xilinx Kintex 7 125K (user programmable) Xilinx Artix 7 35T (auxiliary) |

| Analog inputs | 16x 16bits @500ksps Simultaneous sampling Programmable full-differential front-end |

| PWM outputs | 16x Optical 32x Electrical (3.3V) |

| User High-speed I/Os | 36x Electrical (3.3V) |

| Digital outputs | 16x Electrical (3.3V/5.0V) |

| Digital inputs | 16x Electrical (3.3V/5.0V) |

| Fault inputs | 16x Electrical (3.3V) 1x Electrical interlock 1x Optical interlock |

| Encoder inputs | 4x 3-pins (A,B,Z) (shared with GPI inputs) |

| Communication | 1x CAN 1x Ethernet 1 Gbps 3x SFP+ 5Gbps (RealSync) |

Switch from simulation to experimentation in no time!

The B-Box RCP can be programmed in one click, directly from Simulink. Besides, everything can be accurately simulated first. This allows a truly simple and rapid switchover to lab activities.

Go early to the lab and work straight ahead with power!

With the hardware protections present with the control hardware, engineers can start testing early, saving valuable time on computer simulations and/or real-time simulations.

Generate high quality and impactful experimental results!

Thanks to the data logger embedded directly inside in the programmable converter controller, every signal can be observed, tuned and logged during run time.

An advanced prototyping controller

The RCP controller target supports the implementation and real-time tuning of the most advanced digital control techniques for power converters. This requires not only excellent performance but also a high level of flexibility and ease of use.

Integrated with Simulink and PLECS

The B-Box RCP prototyping controller can be programmed using C/C++, or simulation software such as Simulink or PLECS. Thanks to our fully-automated code generation toolchain, just one single click is needed to fully program the device!

The blocksets also embed simulation models so that the system can be accurately simulated and tuned before code is generated.

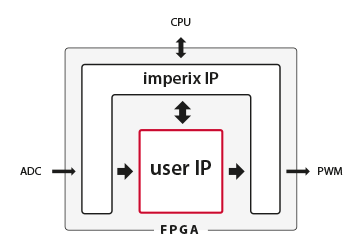

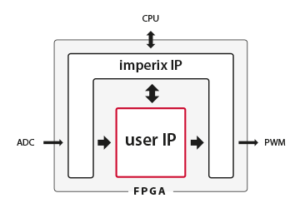

Absolutely no expertise in FPGA-based development is needed to work with the B-Box RCP. It operates readily with a very flexible and entirely configurable FPGA firmware.

Nevertheless, for the advanced users who require rapid control prototyping to involve custom FPGA code, the RCP target allows doing so. Dedicated FPGA areas are provided, with straightforward integration with DSP software.

User-programmable FPGA

High processing power

The B-Box RCP uses a dual-core processor (Xilinx Zynq). One DSP core is dedicated to the real-time control tasks (bare metal, dedicated kernel), the other one to the system supervision and monitoring (Linux). Most low-level tasks are also shifted in FPGA.

This results in the full dedication of a fast floating-point processor (DSP) to power converter control purposes, with tremendous performance, ranging up to 250 kHz control frequencies in closed-loop operation.

In stacked configurations, all units are naturally synchronized with an accuracy of ±2 ns (!) thanks to imperix’s RealSync technology. This allows using all I/Os as if they simply belonged to the same controller hardware!

Stackable design

Hardware-level protection

In case of inappropriate operation, the controller instantly blocks its PWM signals, thanks to dedicated hardware protection circuits. This guarantees excellent protection, entirely independently from both the DSP cores and the FPGA.

The B-Box RCP prototyping controller is also self-protected against inappropriate conditions such as excessive computational burden or algorithmic errors.

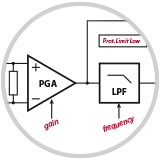

Each rapid prototyping controller possesses 16 fully configurable analog input channels. This obviates the need to repeatedly develop signal conditioning interfaces for every project. Each input channel features:

- 3kΩ differential voltage input or 100Ω single-ended current-type input.

- Programmable safety thresholds.

- Programmable gain amplifier and low-pass filter

Fully-configurable analog front-end

An advanced rapid protyping controller

Integrated with Simulink and PLECS

|  |

The B-Box RCP can be programmed using C/C++ code, or widespread simulation software, such as Matlab Simulink or Plexim PLECS. Thanks to a fully automated code generation toolchain, just one single click is all it needs to fully program the device!

The blocksets also embed simulation models so that the system can be accurately simulated and tuned (offline and in real-time).

User-programmable FPGA

|  |

Absolutely no expertise in FPGA-based development is needed to work with the B-Box RCP rapid prototyping controller. It operates readily with a very flexible and entirely configurable FPGA firmware.

Nevertheless, for the most advanced users who require to alter the FPGA code, the B-Box RCP allows doing so. Dedicated FPGA areas are provided, with straightforward integration within the existing DSP software kernel.

High processing power

|  |

The B-Box RCP uses a dual-core processor (DSP) ; one DSP core being dedicated to the execution of the closed-loop control tasks (bare metal, dedicated kernel), the other to the system supervision and monitoring (linux). Besides, most low-level tasks are shifted in FPGA.

This results in the full dedication of a fast floating-point processor core to real-time control tasks, with best-in-class performance, ranging up to 250 kHz control frequencies.

Stackable design

|  |

In stacked configurations, all units are naturally synchronized with an accuracy of ±2 ns (!) thanks to imperix’s patent-pending RealSync technology. This allows using all I/Os as if they simply belonged to the same rapid prototyping controller hardware.

Hardware-level protection

|  |

In case of inappropriate operation, the B-Box RCP controller instantly blocks its PWM signals, thanks to dedicated hardware protection circuits. This guarantees rigorous protection, entirely independently from both the DSP cores and the FPGA.

The rapid prototyping controller is also self-protected against inappropriate conditions such as excessive computational burden or critical algorithmic errors.

Fully-configurable front-end

|  |

Each B-Box possesses 16 highly configurable analog input channels. This obviates the need to repeatedly develop signal conditioning interfaces for each prototyping project. Each input channel features:

- 3kΩ full-differential voltage input or 100Ω single-ended current-type input.

- Programmable safety thresholds.

- Programmable gain amplifier and low-pass filter

A fully-programmable prototyping controller

Rapid control prototyping with both DSP + FPGA

DSP programming

- Simulink and PLECS

- C/C++

FPGA programming

- VHDL, Verilog

- High-level synthesis

B-Board PRO inside!

A high-performance embeddable controller at the heart of each real-time control target

The B-Board PRO control module is used as the main processing system inside the B-Box RCP.

This guarantees consistent behavior and performance between both platforms, enabling users to switch seamlessly between them, with full bitfile compatibility.

Networked control technology

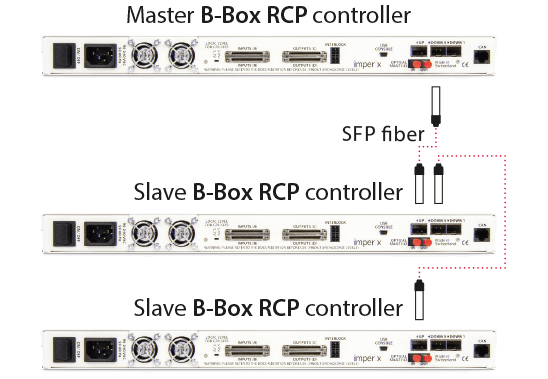

Multiple RCP controllers can be interconnected using optical fibers (SFP). In this case, the I/O capabilities of the so-constituted RCP control target can be vastly augmented, as well as its processing power.

Perfect synchronization

Imperix’s patent-pending RealSync technology guarantees an unrivaled synchronization accuracy across multiple units, down to ±2.0 ns!

This is achieved through advanced clock dissemination in the optical fibers, enabling multiple B-Box RCPs to operate as if they were one single unit!

Low-latency communication

The same 5 Gbps SFP+ links can be configured in a tree-shaped network, achieving superior data bandwidth and lower latency over daisy-chain or ring topologies. This guarantees sub-microsecond data transfers in configurations with up to 8 programmable RCP controllers!

Ultimately, this ultra-fast data transfer enables the implementation of distributed control strategies over the whole network.

Inter-devices communication can be used to build larger programmable targets or in-between multiple converter controllers.

A tailor-made kernel

The core of the programmable controller

The B-Box RCP rapid prototyping controller embeds an ultra-light operating system, specially tailored for hard real-time operation, as in power electronics. This kernel simultaneously combines rigorous safety mechanisms and a very low overhead.

More importantly, thanks to its fully FPGA-based peripherals, the RCP controller is built on a strong hardware abstraction layer. As such, any control code is guaranteed to keep working across future generations of hardware, facilitating system maintenance and upgrade.

A nice benefit of this approach is also that B-Box RCP and B-Board PRO are fully cross-compatible, although the underlying hardware differs. This allows users to switch from one control hardware to the other very easily.

Comprehensive computer software

Tools dedicated to the control of power converters

Comprehensive design suites

Rapid control prototyping with our programmable controllers is supported by our software development kits (SDK), for either C++, Simulink or PLECS.

- Support for C++, Simulink, or PLECS

- Code libraries/examples

- Free maintenance

Monitoring & control software

During operation, Imperix Cockpit allows observing, editing and logging any variable. This facilitates the rapid debugging and tuning of any converter control code.

- Real-time tuning of all variables

- 2 million points datalogging

- Free maintenance